Sarah had been waiting three years for her contractor to finish her kitchen renovation. What started as a six-week project stretched into seasons of dust, delays, and mounting costs. Every morning brought new excuses about supply chains, weather, or workers calling in sick. She watched her savings drain away while living with plastic sheets for walls.

Meanwhile, 500 miles away, a family watched their entire home take shape in less time than Sarah’s kitchen had been under construction. No delays. No excuses. Just a robot methodically building their 200-square-meter dream home in 24 hours.

This isn’t science fiction anymore. Robotic home construction has arrived, and it’s about to change everything we thought we knew about building houses.

The Silent Revolution on Construction Sites

Walk past a traditional construction site and you’ll hear the familiar symphony of chaos: jackhammers pounding, workers shouting over machinery, radios blasting to compete with the noise. But robotic construction sites tell a different story entirely.

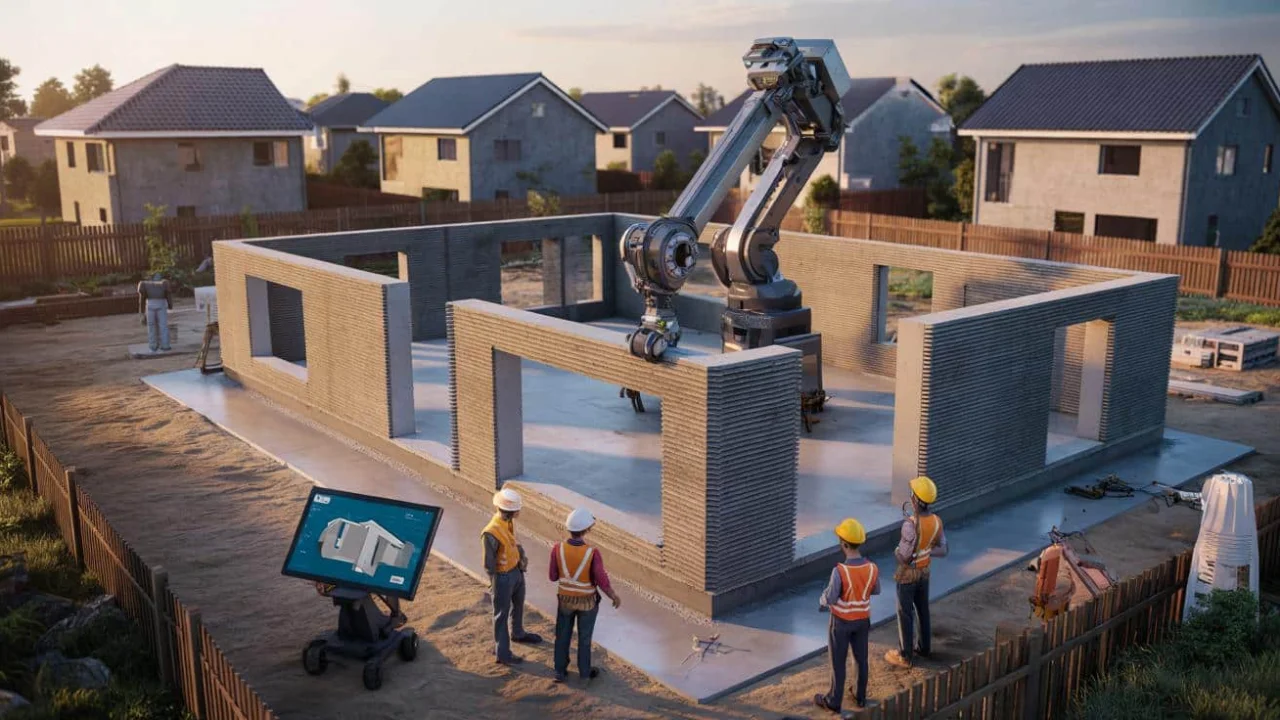

There’s an eerie quiet broken only by the soft mechanical hum of a massive robotic arm. No cigarette breaks, no arguments about blueprints, no weather delays. Just precise, methodical movement as the machine extrudes concrete like frosting, layer by layer, following digital plans down to the millimeter.

“The first time I watched one of these robots work, I couldn’t believe my eyes,” says Maria Rodriguez, a construction project manager who witnessed a recent demonstration. “By lunch break, we had walls where there was empty ground that morning.”

The technology works like a giant 3D printer, but instead of plastic filament, it uses specially formulated concrete mixtures. The robotic arm follows precise coordinates from architectural software, building walls, rooms, and even complex curved structures with mathematical precision.

What makes this particularly revolutionary is the speed. Traditional construction of a 200-square-meter home typically takes 4-6 months. These robotic systems can complete the same structural work in a single day.

Breaking Down the Numbers and Technology

The specifications behind robotic home construction reveal why this technology represents such a massive leap forward:

| Aspect | Traditional Construction | Robotic Construction |

|---|---|---|

| Build Time (200m² home) | 4-6 months | 24 hours |

| Labor Required | 8-12 workers | 2-3 operators |

| Material Waste | 15-20% | 2-5% |

| Precision Tolerance | ±10-15mm | ±2mm |

| Weather Dependence | High | Minimal |

The key advantages go beyond just speed:

- Precision: Robots don’t get tired, distracted, or make human errors

- Consistency: Every wall, corner, and opening meets exact specifications

- Material efficiency: Concrete is deposited only where needed, reducing waste

- Safety: Fewer workers on-site means reduced accident risk

- Cost predictability: No surprise labor costs or schedule overruns

“We’re seeing 40-60% cost reductions compared to traditional methods,” explains Dr. James Chen, a construction technology researcher. “When you eliminate most labor costs and material waste, the economics become compelling very quickly.”

The concrete mixture itself has been specially engineered for robotic application. It needs to flow smoothly through the printing nozzle while setting quickly enough to support subsequent layers. Some formulations include additives that accelerate curing or improve insulation properties.

Current systems can handle complex architectural features too. Curved walls, integrated ducting for utilities, and even decorative elements can all be printed directly into the structure. The robot doesn’t care if your design calls for straight walls or flowing organic shapes.

Real-World Impact on Housing and Communities

The implications stretch far beyond faster construction timelines. Housing affordability has reached crisis levels in many countries, with young families priced out of homeownership entirely. Robotic home construction could be the key to unlocking affordable housing at scale.

Consider the math: if construction costs drop by 50% and build times shrink from months to days, suddenly housing becomes accessible to millions more families. Developers could respond to demand almost immediately rather than planning years in advance.

“This technology could finally allow us to build affordable housing that’s actually affordable,” says housing advocate Lisa Thompson. “We’re not just talking about cost savings – we’re talking about fundamentally changing how quickly communities can respond to housing needs.”

Disaster relief represents another game-changing application. After hurricanes, earthquakes, or floods, communities often wait months or years for rebuilt housing. Robotic construction could provide permanent shelter within days of a disaster, not temporary FEMA trailers that become permanent fixtures.

Rural communities face unique benefits too. Construction labor shortages hit rural areas hardest, often making new housing projects economically impossible. A robotic system can be transported anywhere and doesn’t require a large skilled workforce.

The environmental impact deserves attention as well. Construction waste represents roughly 30% of all landfill content. When robots use exactly the amount of concrete needed – no more, no less – that waste stream shrinks dramatically. The shorter construction timeline also means less disruption to surrounding ecosystems.

Early adopters are already moving beyond pilot projects. Several European countries have approved robotic construction for certain building types. The Netherlands recently completed its first permitted robotic home, lived in by a real family who reports the walls are perfectly straight and the rooms stay remarkably warm in winter.

“The quality actually exceeds what human builders typically achieve,” notes the homeowner. “There are no gaps, no settling cracks, no uneven surfaces. It’s like living inside a precision instrument.”

Regulatory approval remains the biggest hurdle. Building codes written for traditional construction methods don’t account for robotic techniques. Some jurisdictions are updating regulations, but progress remains slow in many areas.

Labor unions express understandable concerns about job displacement, though proponents argue the technology will create new roles in robot operation, maintenance, and programming. The transition period will require careful management to retrain displaced workers.

For families like Sarah, still waiting for basic renovations, robotic construction represents hope. The technology promises not just faster building, but predictable timelines, fixed costs, and quality that doesn’t depend on whether the contractor had a good day.

The silent revolution has begun. Soon, the sounds of traditional construction sites – the delays, the frustrations, the cost overruns – might become as obsolete as typewriters in a smartphone world.

FAQs

How much does robotic home construction actually cost?

Current estimates suggest 40-60% cost reduction compared to traditional building, though exact prices vary by location and home design.

Are robotically built homes as strong as traditionally built ones?

Yes, the precision of robotic construction often results in stronger, more consistent structures with better insulation and fewer weak points.

Can these robots build multi-story homes?

Current technology primarily handles single-story construction, though multi-story capabilities are being developed and tested.

What about plumbing, electrical, and other systems?

Robots currently handle structural elements, while human workers install utilities, windows, doors, and finishing work.

When will this technology be widely available?

Some regions already permit robotic construction, but widespread adoption likely requires 2-5 years for regulatory approval and scaling production.

Do robotically built homes look different from regular houses?

The finished homes can look identical to traditionally built houses, though the technology also enables unique curved and custom designs impossible with conventional methods.