Marcus had been working at the same garage for fifteen years when the letter arrived. The local council was expanding the low-emission zone, and his small repair shop would need to relocate or shut down by 2027. He stared at the notice, then walked over to the 1991 Audi Quattro he’d been restoring in his spare time. The five-cylinder engine sat there, silent but somehow defiant.

“Forty years this configuration has been around,” he muttered to his apprentice. “Now they’re telling us it’s finished.”

But in a workshop somewhere in Europe, engineers are proving Marcus—and the bureaucrats—wrong. They’ve taken that classic five-cylinder layout and turned it into something that could rewrite the rules of what petrol engines can achieve in our electric future.

The screaming anomaly that refuses to die

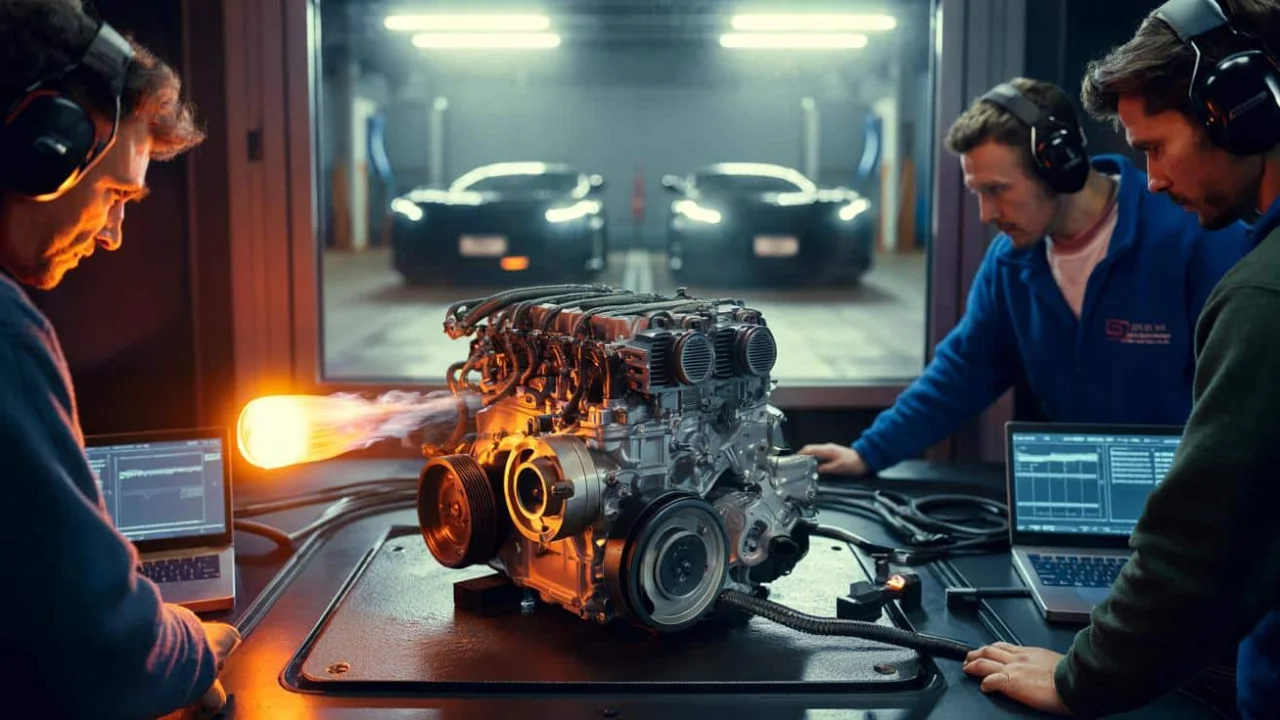

The 5 cylinder engine spinning on the test bench doesn’t sound like any car you’ve heard before. At 16,000 rpm, it produces a metallic shriek that’s part Formula 1, part superbike, and completely unlike the familiar rumble we associate with road cars.

This isn’t just another engineering exercise. While European lawmakers prepare combustion engine bans and charging infrastructure spreads across cities, this little powerplant represents something bigger: the final, desperate attempt to prove that petrol engines still have a future.

“We’re not trying to compete with electric motors on efficiency,” explains Dr. Elena Kowalski, a powertrain engineer who’s spent the last three years refining high-rev gasoline technology. “We’re trying to create something electric simply cannot replicate—the emotional connection between driver and machine.”

The numbers tell an extraordinary story. From a displacement smaller than most motorcycle engines, this 5 cylinder engine produces 240 horsepower. That’s nearly 200 hp per liter—territory usually reserved for Formula 1 cars, not road-legal vehicles.

Engineering madness meets real-world constraints

Building an engine that can survive 16,000 rpm while meeting modern emissions standards requires rethinking almost everything we know about internal combustion.

| Component | Traditional Engine | High-Rev 5-Cylinder |

|---|---|---|

| Piston Weight | 400-600g | 180-220g |

| Redline | 6,000-7,000 rpm | 16,000 rpm |

| Power/Liter | 80-120 hp | ~200 hp |

| Fuel Injection | Port/Direct | Ultra-high pressure direct |

The engineering challenges are immense:

- Pistons made from aerospace-grade materials to withstand extreme forces

- Connecting rods lighter than a smartphone but stronger than traditional steel

- Valvetrain components that open and close 266 times per second at peak rpm

- Fuel injection systems operating at pressures that would make diesel engines jealous

- Cooling systems that manage heat loads exceeding most race cars

“Every component has to be perfect,” notes Francesco Bernardi, a former MotoGP engineer now working on automotive applications. “One weak link and the whole thing destroys itself in seconds.”

The five-cylinder configuration offers unique advantages for this extreme application. Unlike four-cylinder engines, which suffer from inherent vibration issues at high rpm, or V6 engines that become too complex and heavy, the inline-five provides the perfect balance of power, smoothness, and compact packaging.

Fighting for survival in an electric world

This isn’t just about building a faster engine. It’s about proving that internal combustion still has something unique to offer as Europe prepares to ban new petrol car sales by 2035.

The project team believes their high-revving 5 cylinder engine could find homes in several niche applications:

- Lightweight sports cars where every kilogram matters

- Track-focused vehicles that prioritize emotion over efficiency

- Hybrid supercars needing compact, high-output range extenders

- Racing series that maintain combustion engine regulations

“Electric motors are incredible for acceleration and efficiency,” admits Kowalski. “But they’re silent. They don’t have a soul. This engine is all soul.”

The reality is sobering, though. Even if this technology proves viable, the market for it will be tiny. Most drivers want quiet, efficient transportation that starts every morning and never needs attention. This screaming five-cylinder monument to combustion engineering appeals to maybe one percent of car buyers.

But that one percent matters. They’re the enthusiasts who keep classic cars alive, who attend track days, who understand that driving can be about more than getting from point A to point B. They’re Marcus, staring at his Audi Quattro and wondering if this is really the end.

“We’re not building this for everyone,” Bernardi acknowledges. “We’re building it for the people who understand why it matters.”

The prototype has already attracted interest from several small-volume manufacturers. Companies that build a few hundred cars per year, not hundreds of thousands. Firms that cater to customers willing to pay premium prices for unique experiences.

Whether this 5 cylinder engine can find commercial success remains uncertain. The development costs are enormous, the market is shrinking, and every year brings new regulations that make high-performance combustion engines harder to justify.

Yet the engineers keep refining it, pushing the rev limit higher, extracting more power, making it cleaner. Because sometimes the fight itself matters more than the outcome. Sometimes you build something not because it makes business sense, but because the alternative—letting it die without trying—is unthinkable.

In workshops across Europe, the sound of high-revving engines still echoes. For now, at least, petrol is learning to scream louder than ever.

FAQs

How can a 5 cylinder engine rev to 16,000 rpm safely?

Ultra-lightweight components, aerospace materials, and precision balancing allow these engines to spin far beyond traditional limits while maintaining reliability.

Why choose five cylinders instead of four or six?

Five cylinders offer better balance than four-cylinder engines at high rpm while staying more compact and lighter than six-cylinder configurations.

Will this engine meet modern emissions standards?

Yes, advanced fuel injection, exhaust aftertreatment, and combustion optimization help it comply with current and future European regulations.

How much would a car with this engine cost?

Given the specialized nature and low-volume production, expect prices in the exotic sports car range—likely $150,000 and up.

Could this technology be used in hybrid systems?

Absolutely—the compact, high-output nature makes it ideal as a range extender or performance boost in hybrid supercars.

When might we see this engine in production cars?

If development continues successfully, limited production could begin as early as 2027, though only in very low volumes initially.